Blue®Control RF (Recovery Fuels) software is an ERP system based on modular project design, which makes it extremely flexible and versatile for various industries. Mainly dedicated for the industrial sector: cement plants, lime plants, waste treatment plants or biomass, power plants: CHP plants, thermal power plants.

The modular project design of the system makes it easy to adapt to the needs of the customer, systematically expanded and, most importantly - suitable integration systems successfully connected with existing processes, devices or programs.

Blue®Control has a lot of possibilities. Software is so easy in use which makes it usefull in industry.

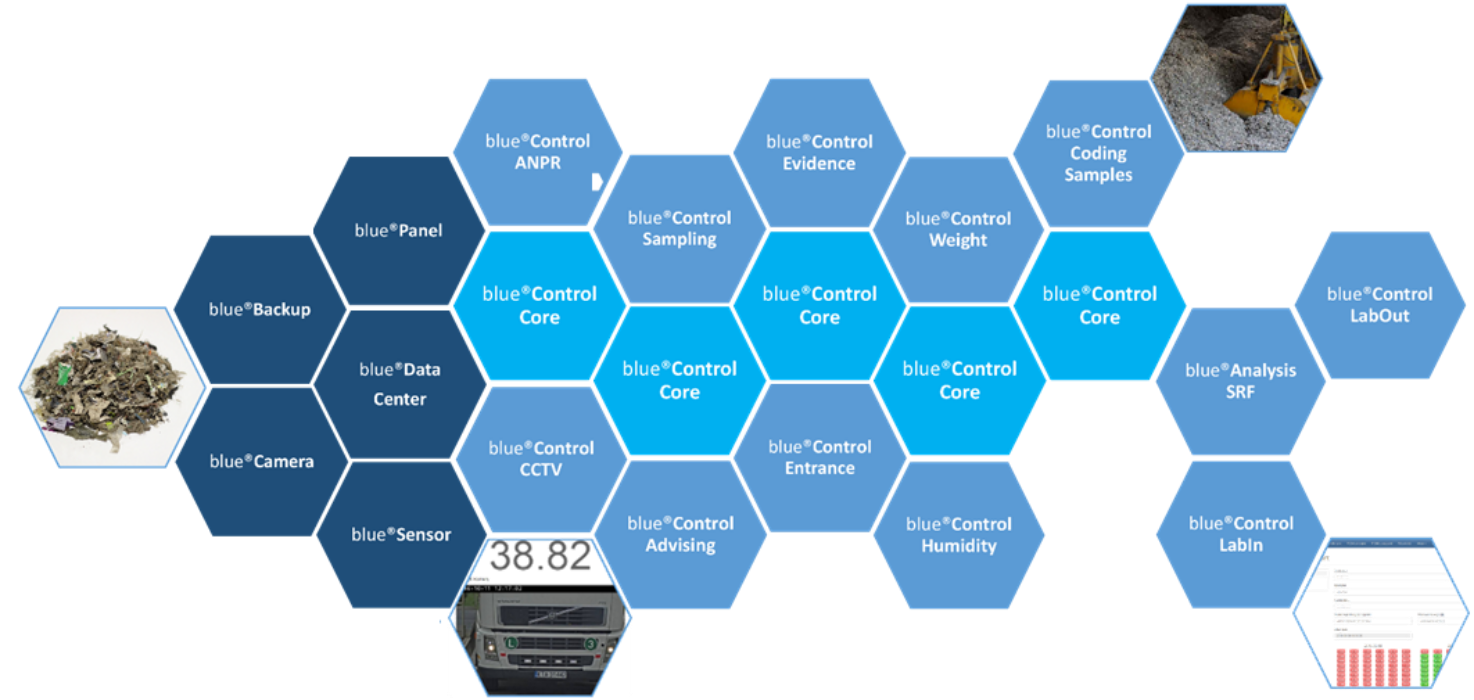

The system consists of two main components: hardware and software. Each of them includes several smaller modules so that they can perfectly match for your needs.

The main hardware module is blue®Data Center, which is an extensive database with server infrastructure and complementary modules, among others. For backing up, operating devices or operator stations.

The software area is based on blue®Control Core, an integrator of the remaining functional and functional modules. This module supervises in its structure:

• A database of information, in this case alternative fuel by the plant - Delivery dates, tonne, supplier data, shippers, physicochemical parameters of alternative fuels

• In the form of algorithms they know about the procedures for proper process of supervising the processing of alternative fuels by the plant.

• Validation and processing of data: mediates the flow of information between the server interfaces supported by the web server and the database; It processes and validates collected information into formats accepted by the database.

• Web-based communication: Provides communication between individual system modules, between modules and operator terminals, and enables system users to access external resources, such as the Plant Management.